By using a steel construction it is possible to build your home without interior walls. This makes it easy to adjust the layout of the house. It is therefore always possible to adapt your home to the changed living conditions and this only by moving, adding or removing walls. Building your own floor can not be a problem.

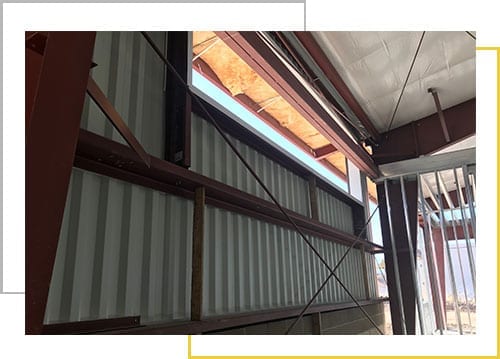

In metal frame construction, the load-bearing structure consists of a skeleton, made up of columns and beams. These are hot rolled steel profiles. The architectural advantage of metal frame building construction is that the walls are not load-bearing and therefore the compartmentation can be completed relatively arbitrarily, without significant additional costs. In other words, there is a separation between the supporting structure and the content, which allows flexibility.

Rapidset Metal Buildings offers a number of undeniable advantages, such as a lower construction cost and faster realization. Metal frame buildings belong to the so-called dry construction methods, which means that the construction is prepared in the workshop and that the various components are assembled on the construction site in a manageable period. Because people are less dependent on the weather conditions, the house can be realized faster. Because the house contains little building moisture, it can also be finished faster. The non-load-bearing inner walls can be placed by means of light style walls covered with plasterboard. This makes it easy to remove the pipes from the techniques. The finish of the hull is therefore particularly suitable for self-construction.

The biggest architectural difference in steel construction houses with other construction methods (traditional, timber frame, …) is the construction.

Due to the use of steel columns and beams that determine the structure of the building, there are no load-bearing walls, even the outer walls are not load-bearing.

On the outside, this ensures a free choice of materialization, on the inside, this translates into a free plan.

This means that because there are just no load-bearing walls, large open spaces can be created and a flexible (later interpretation) is perfectly possible.

Maximum (design) freedom is therefore the greatest asset of a steel construction house.

A second major advantage of building in steel is the speed with which it can be built. If one considers that the steel or metal structure of an average house is assembled in 2 to 3 days and that due to a possible high degree of prefabrication of the further finishing, the house can be made wind and watertight within 1 month, then this yields an enormous profit. in total construction time.

The concept of a steel construction house ensures rapid weather-independent realization.

Standard construction

- Foundation soles instead of continuous foundation

- Structure in steel (columns and beams)

- Ground floor slab in in-situ concrete

- Intermediate floors in prefab concrete elements (vaults / broad floor slabs) Roof slab in precast concrete

- Elements or profiled steel plates

- Facades erected in steel sandwich panels (thickness in accordance with insulation requirements)

- Facade finish of your choice

Constructive (structure)

- Light structure

- Very dimensionally stable

- Limited foundations

- No load-bearing walls

- Flexible space layout / open layout/loft feeling

- Simple and budget-friendly to design with higher spaces

- Pitched roof / flat roof

Constructive (floor slabs in concrete)

- Thermal inertia compensation

- Limited sound transmission

Aesthetic

- 100% free choice of materials (facade/room layout)

- Free facade layout – large windows

- Maximum design freedom

- Independent of the desired architectural style

- Wide choice of finish

Ecological

- Steel: 100% recyclable material

- Energy-saving – maximum insulation values

- No thermal bridges

- Easy to conceive as a passive house

Budgetary

- Prefabrication ensures a shorter implementation period and therefore savings in working hours

- A rapid succession of the different construction phases

- Weather-independent construction/handling of planning

- Due to the extremely high degree of work preparation, unforeseen issues are excluded on-site (reduction of settlements)

Unique and comfortable

Fancy large, high, free spaces, lots of glass, and light? And in special detailing and finish? Then a house with a steel construction or steel facade is very suitable.

Steel construction has a skeletal structure, with columns and girders, between which or against which the other building parts are mounted. In this way, almost all conceivable shapes and dimensions of the building can be made, without immovable walls and floors. All materials and distances are possible, making each home unique. The transitions from living rooms to kitchens or, for example, from bedrooms to (roof) terraces become playful.

Fast construction time

Steel is light and available in large or proper handy parts. The house can largely be prefabricated in the factory. The construction time on location is thus reduced to a minimum and the house is also of high quality.

Growing with it

Because steel construction is based on a skeletal structure, it is also easy to expand or adapt at a later date. Larger spaces can be reduced, but with the same ease, several smaller spaces can be merged into one large one. All kinds of additional parts can also be mounted on the steel construction, such as awnings, conservatories, or, for example, an entire kitchen.

There is a misconception about steel that it is ‘cold’ and ‘cool’. The many villas in the Netherlands now prove that the indoor climate can be very pleasant. Also because of the choice of finish. Energy bills do not have to be higher than with conventional construction. In fact, metal construction ‘naturally’ has spaces that are filled with insulation material, so that high insulation values can be achieved.

Sustainable

An extra strong side of steel is the fact that it is 100% recyclable and therefore a sustainable building material. All steel can be selected magnetically during demolition or disassembly and, for example, processed in other (new) construction. Approx. 51% is reused in this way. If that is not possible, it can be returned to the steelmaking process. About 49% of the construction material is returned to the cycles.